| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : BEAKELAND

Model Number : 1000KG/H

Certification : CE

Place of Origin : JIANGSU,CHINA

MOQ : 1 SET

Price : Negotiation

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 8 SET/ YEAR

Delivery Time : 65~80 WORKING DAYS

Packaging Details : Wooden case packing for LCL shipment, Film wrap packing for FCL shipment.

Name : PET Flakes Hot Washing Recycling Line

Application : PET Bottle Recycling and Processing

Process : Debaler,Delable,Sorting,Crush,Wash,Drying

Production Capacity : 1000kg/h

Raw material : Waste PET Bottles

Final products : Clean flakes 8-16mm(customized)

Crusher model : 1200

Hot washing : by steam heating or electrical heating

Keyword : PET recycling line

300-3000 Kg / H PET Flakes Hot Washing Recycling Line / PET Recycling Line

Description:

The waste PET bottle crushing washing recycling machine line is used for crushing, cleaning, separation of bottle cap and label, depriving of impurity and glue material, and drying for bottle flakes. Then those waste PET bottle will become reusing PET materials.

We have several different standards of PET bottle crushing washing recycling machine line according to different production capacity and requirement for cleaning (capacity of 300-3000kg/h).

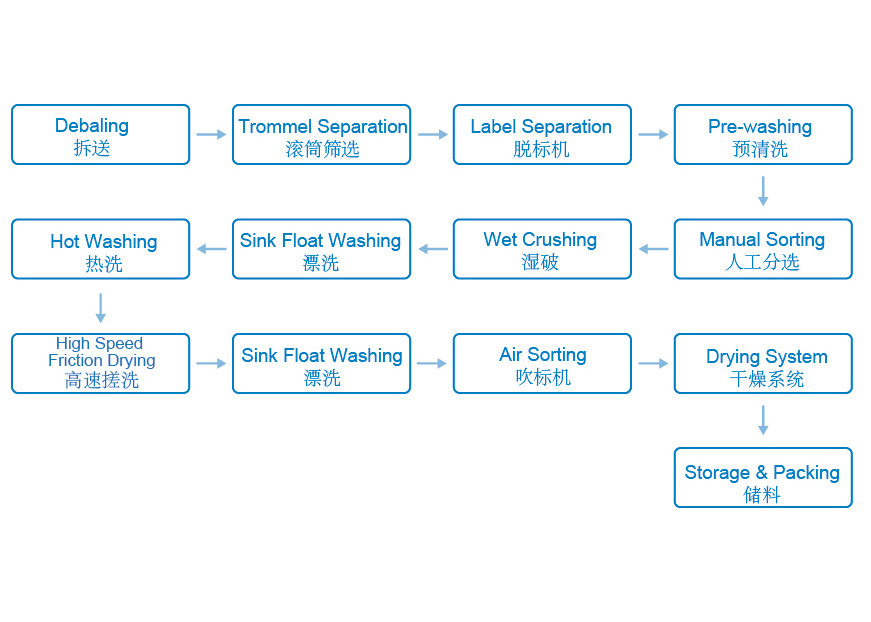

PET Recycling Equipment process:

Models&specifications of PET Recycling Equipment :

| Model | BKL-500 | BKL-1000 | BKL-1500 | BKL-2000 | BKL-3000 |

| Capacity(kg/h) | 500 | 1000 | 1500 | 2000 | 3000 |

| Installation Power (kw) | 150 | 250 | 300 | 400 | 500 |

| Man power | 4-6 person | 6-8 person | 8-10 person | 10-12 person | 12-16 person |

| Water supply | 4-5m3/hr | 8-10m3/hr | 8-12m3/hr | 10-15 m3/hr | 20-30 m3/hr |

Key Machine function in the PET recycling line :

Label Remover Machine

Function:remove the labels from the bottle and separate label out from bottles Blade made by alloyed steel for long time use Blade is fixed by screw on the rotor easy to adjustable and changeable The barrel designed with doors opening on it very easy to opening and maintenance The machine bottom with holes to drain out liquid which contained in the bottles, good for machine use

Crusher Machine

Function: crushing the bottles to PET flakes,with water inlet do wet crushing Chamber opened by screw motor

Specially designed PET bottle Crusher Machine can easily get high output and with water doing wet griding can extension the blades use life, reduce the dust generation. Bearing house is outside of the crusher chamber so no dirty goes inside for longer use.

Hot Washing Tank

Function: with hot water washing to remove oil/glue and other dirty from the flakes The tank made with insulation layer to save energy.Feeding caustic soda/detergent to washing Its better Heating by steam, can buy a steam boiler to produce the steam, the boiler can heating up by gas/diesel/petrol/LPG

“Zig-zag” label separator

The Fin dust separator machine will remove the final labels from the flakes to guarantee the PVC content. Blower with air flow adjustable,With valve to control the air flux of blower. Zig zag main chamber one set made by stainless steel,Chamber with plexiglass window to open and check inside

Photos of PET Recycling lines:

|

|

Debaler Pet Flakes Hot Washing Machine 1500Kg H Plastic Washing Plant Images |